Yes, you read that right… how to brew non alcoholic beer!

Non-alcoholic beer on tap – right where you are.

More to the point, over the past years…

…sales of non-alcoholic beer has shot up to 75% – and is expected to grow further still!

If you’re curious about this thing, they call beer, tastes like beer, and has no bad side?

Keep scrolling to know why and how non-alcoholic beer is made.

Why Non-Alcoholic Beer Is Made

If you look at the UK National Statistics…

26% of males and 31% of females aged 16-24 years old haven’t drunk alcoholic drinks.

There’s a lot of reasons why – health for one.

That said…

Non-alcoholic beer manufacturers continue to innovate products for a growing market of health-conscious consumers.

Because whether you believe it or not…

There’s an increase in demand for low-alcohol beer and non-alcoholic beers from people with health issues due to alcohol intake.

Now…

You can find on the market completely alcohol-free beers that contain only 13 calories, are vegan friendly, and are gluten-free.

Who wouldn’t be enticed by that, right?

Out there on the market is a dark stout with a full-bodied mouthfeel and toasty finish.

wait for it…

…accented with coffee and bittersweet chocolate. I know, mouth-watering!

You see…

Alcohol-free beer generally contains little to no alcohol content – ranges from 0% to 12% ABV.

Plus, a brewing company said that…

…consumption of alcohol-free beer improves cardiovascular health and increases bone mineral density.

But, not just that!

It also reduces the risk of osteoporosis and stimulates breast milk production.

That said…

More and more people switch from standard beer to non-alcohol beer.

Even young beer consumers are willing to do the same.

Additionally, to reduce or remove alcohol…

Homebrewers are looking for ways to hone their brewing skills.

If you’re one of them…

… you’ll agree that making non-alcoholic beer isn’t as simple as one, two, three.

It’s like a new crash course in brewing.

Creating a NAB – takes a lot of practice, skills, and technique.

So, keep your head high because your own non-alcoholic beer is yet to come.

Techniques Suited To Homebrewers

There are techniques that could influence the brewing process of homebrewers.

Yet…

Some techniques may be unsuitable. This is due to accessible yeast strains and equipment restrictions. Thus, selecting one that will suit them is critical to their success.

Step 1: Make Beer As Usual

First, we need to understand how regular beer is made.

If you’re a first-time brewer…

It’s recommended that you start making alcoholic beer to grasp the process. You can also opt to buy a fresh wort brewing kit – add water, yeast, and you have a beer.

To continue…

Beer is made by mashing malted barley with hot water to extract more complex sugars and create a wort.

The wort is then boiled with hops and yeast. The yeast would then eat the sugars in the wort. Turn them into ethanol and other compounds that add flavor.

So, now…

Let’s see how the non-alcoholic version is produced. There are many different ways to make it, and here are some methods you should know.

High temperature/low gravity

Mash at a high temperature of 162-180 degrees Fahrenheit/72-82 degrees Celsius. This enhances alpha-amylase enzyme activity which results in a more dextrinous wort. Thus, less fermentable wort with superb mouthfeel, taste, and head retention beer!

Furthermore…

This process produces worts with strengths ranging from 1.005 OG to 1.030 OG (OG: original gravity), resulting in a low ABV beer ranging from 0.1 to 2.0%.

This is the most user-friendly approach for producing non-alcoholic or low ABV beers.

It can be done on small-scale systems, plus, straightforward and cost-efficient.

Cold mashing

This method involves crushing the grains for 1-24 hours in cold water.

The grains from the wort were removed then…

…brought to a standard mash temperature for 10 minutes. This was done to cut the presence of unconverted starches. Before proceeding to a regular boil for hop additions and clarifying agents.

Now…

Passive extraction is the primary notion of cold mashing – which may perform by letting the grain react with cold water at refrigerator temperatures for 8+ hours.

If the mashing vessel is stirred…

…this response can be decreased to as little as 1 hour, and one method is to recirculate the sweet wort continually.

Worts produced by the cold mashing include much more of the proteins necessary for superior head retention and mouthfeel.

Even when cold mashing, a regular strength recipe…

…the ABV of the resulting beer will generally be between 1 and 1.5 percent while preserving full flavor, great body, and quality foam.

Influencing the fermentation process

During the brewing process…

Limiting the amount of alcohol produced to under 0.5% – you’ll have an alcohol-free beer.

Moreover…

The yeast produces alcohol from the fermentable sugars in beer wort.

If the yeast strain is less effective…

…that means – the alcohol content remains small, especially in a low fermentation temperature.

That said…

…reducing the quantity of fermentable sugar in the wort would make a low alcohol beer from the start.

The less sugar the yeast can ferment – the less alcohol produced.

Another good thing is…

Brewers can utilize grains that yield less fermentable sugars, such as rice or corn sugar.

Or…

…by removing fewer fermentable sugars from grains during the mashing step of the brewing process.

Stopping the fermentation process

Furthermore…

You can also make non-alcoholic beer by stopping the fermentation process.

This process involves killing the yeast or heating up or filtering the yeast away.

Keep scrolling to know more…

Step 2: Alcohol Removal Process

Removing the alcohol from the finished product is the most popular method.

First…

You’ll let the beer fully ferment after the alcohol is distilled off from the finished product.

During this method…

…flavors also evaporate from the beer, but they can be recovered and restored to the beer afterward.

The boil-off method

This method of removing alcohol from beer is the most approachable to homebrewers.

Just so you know…

Alcohol has a lower boiling point than water. Ethanol evaporates at a lower temperature than water.

So, the alcohol content will evaporate by the boil-off method and leave the water behind.

But, how long does it take to boil the beer?

It’s debatable. Atmospheric pressure and heating temperatures vary from brewer to another making it irregular.

In theory…

It would take 2.5 to 3 hours of heating to decrease a beer with a 5% ABV to 0.5 percent ABV.

However, the issue with this strategy is…

…increased heat, off-characteristics from burnt yeast, and loss of valuable volatile aroma and flavor molecules, the beer develops too bitter flavors.

But, with a few safeguards and a little perseverance…

Homebrewers can achieve great-tasting non-alcoholic beer with the complexity of regular beers.

Heating beer

At this point…

You can choose how to heat your fully-fermented beer. Either oven heating or stovetop heating.

Once you transfer your fully-fermented beer to a stockpot or brew kettle. Place the stockpot or brew kettle inside a preheated oven for 20-30 minutes at 180 degrees Fahrenheit.

Or…

You can also place your stockpot on top of the stove as you watch your brewing thermometer stay at 175 degrees Fahrenheit.

Be extra careful because higher than that would risk the flavor of your beer.

That’s why…

Many would prefer oven heating over stovetop heating because of the even distribution of heat and retaining the flavors of the beer.

But…

Homebrewers commonly use stove heating – not only is it convenient, but you have the advantage of checking the temperature.

Step 3: Save the Flavor

Using new yeast varieties

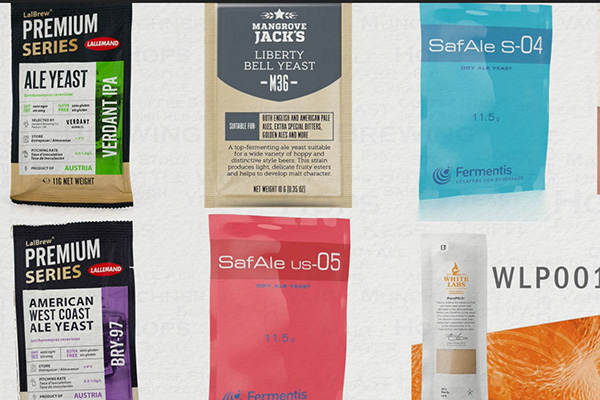

Over the years…

With the rise of non-alcoholic brewing on both the commercial and home brewing markets. Unique yeast strains that are less fermentative are being investigated for their potential.

To develop superior tasting non-alcoholic and low alcohol beer…

…yeast laboratories throughout the globe are experimenting with a variety of new and old strains for a successful fermentation and sensory profiles associated with common brewer’s yeast.

The advantage of employing these yeasts is that the brewer may use an existing recipe with a specific gravity between 1.014 to 1.034 OG.

However…

…because of the increasing amount of unfermented sugars in the non-alcoholic beer.

Pasteurization should be considered to prevent microbial degradation or re-fermentation.

There are several more yeast strains with non-alcoholic beer and low alcoholic beer brewing potential whose microbiological traits have yet to be reported in beer production.

Plus…

This provides considerable opportunity for experimental investigation for laboratories and homebrewers alike.

Step 4: Carbonate Your Beer

As previously mentioned…

Non-alcoholic beers are usually flat because the boil-off procedure removes some of the flavor fragrance from the beer.

But…

Because of the carbon dioxide emission during the boiling process, you are also left with a non-carbonated beer.

You can use either natural or forced carbonation methods to carbonate your beer.

If you opt for natural carbonation…

Before bottling, you’ll need to add more yeast and priming sugar. Before bottling, make sure your yeast is active because unactivated yeast takes longer to carbonate.

If you have another yeast starter that is actively fermenting, we recommend utilizing it to carbonate.

You can also carbonate with the use of simple carbonation tablets. After three days, bottle your beer and serve it.

You may also forcibly carbonate your beer by pumping carbon dioxide into the keg.

If you regularly brew beer…

You may already have some of them laying around. If you don’t have one, you may acquire a carbonation lid kit to assist you in finishing the process.

Alternative carbonation method

Another excellent carbonation method is called Krausening, used to carbonate beer without sugar or other add-ons.

It was a traditional German method – originally developed to initiate a slow and secondary fermentation to reduce unattractive flavor components and produce a superb taste in beer.

Moreover…

Krausening can become organically carbonated on its own if done in a contained tank.

This procedure takes around four weeks, which is typical for most lagers. So, make sure to keep your wort in a sterilized container until needed.

If you plan on using this method…

…set aside about 10 percent of the wort. Some people prefer to use more, but I wouldn’t recommend going above 20 percent.

Once you’ve carbonated your beer…

It would be best to bottle it or leave it in the keg. Then, you’ll be all set to drink your hangover-free beer in no time.

Step 5: Alternate Dealcoholization Methods

Although these methods may not be suitable for homebrewers – they’re still worth mentioning – especially if you’re planning to turn brewing into a business.

Reverse osmosis/filtration method

In reverse osmosis…

The beer is filtered through a membrane separating alcohol and water from the ferment. The alcohol is then distilled out and put the filtered water back in the fermentation mixture.

The reverse osmosis method is quite expensive and takes a lot of equipment.

Vacuum distillation

Moreover…

Vacuum distillation is a technique performed in a vessel where a vacuum is applied.

This method reduces the boiling point of the alcohol to around 120 Fahrenheit or even less.

Though, this isn’t a readily available brewing process for homebrewers.

But…

This gives you an idea because some homebrewers experiment with this technique to get better results for their non-alcoholic beer.

There’s no harm in trying after all.

Conclusion: How To Brew Non-Alcoholic Beer

It’s not harmful to consume alcoholic beverages in moderation…

…but, in some situations, such as allergic or other reactions, you’re simply unable to do so.

Similarly…

Individuals whose health is jeopardized in other ways as a result of alcohol consumption need to take care.

Not to mention beer addicts who overindulge on the beverage.

Thankfully…

Non-alcoholic beer consumption has increased, and additional choices have become available to the masses.

Now…

You can find on the market alcohol-free beers with only 13 calories, that are vegan friendly, and gluten-free.

Some of which improve cardiovascular health, increase bone mineral density, reduce the risk of osteoporosis, and stimulate breast milk production.

If you haven’t been drinking alcoholic beer just yet…

You may try non-alcoholic beers on the market or make your own in the comfort of your home.

But, always, remember – drink responsibly with moderation.

For more – cheers!